|

|

FENDER B-BENDER TECHNICAL INFORMATION

The Fender B Bender was designed by Gene Parsons and Meridian Green and is manufactured by the Fender Musical Instrument Company in Corona, California. It is an extremely robust and well-built unit and when properly set up will provide smooth, silent, trouble and maintenance free operation for many years. Fender B Benders simply do not wear out.

Occasionally problems with the operation of Fender B Bender may arise because of improper assembly or set up. This Tec Sheet is designed to help the guitar technician trouble shoot the cause of problems and assist him/her with appropriate remedies.

PROBLEMS ADDRESSED:

TROUBLE SHOOTING

Problem A: Squeaking sound when Bender is actuated.

If squeaking returns or string breakage is experienced, the bridge saddle may need to be carefully filed and smoothed where the B string contacts it or in rare cases replaced. Some Fender American Standard bridge saddles are made of powdered metal and are crystalline in structure. A coining process done during manufacture of these bridges is intended to harden and smooth the surface of the saddles where the strings contact them. In a few of the early runs, this coining process was not perfected and the smooth surface would wear away quickly, exposing the string to the abrasive and crystalline metal underneath. More recent bridges seem to have solved this problem.

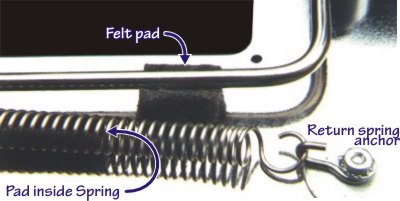

- Possible cause #2: The Return Spring may be rubbing on the side of the Connecting Rod Clevis.

Photo B: Return Spring and Clevis

Photo B: Return Spring and Clevis

- Remedy: Bend the end loop of the Return Spring where it attaches to the Clevis Pin so that the Return Spring is not in contact with the side of the Clevis body.

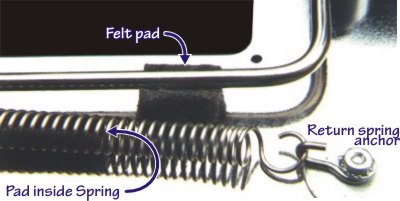

- Possible cause #3: Felt Pad under Connecting Rod is either loose, in wrong position or missing.

Photo C: Felt pads in their correct positions

Photo C: Felt pads in their correct positions

- Remedy: Secure with glue/replace.

- Possible cause #4: In rare instances the Strap Lever may be loose causing it to rub on the surface of the Back Cover Plate.

- Remedy: Tighten screw that fastens the Strap Lever Spindle on to the Back Cover Plate. Make sure all other components are securely fastened and working absolutely freely.

Problem B: Clicking sound when Bender is released, i.e., Strap Lever is allowed to return to home position.

- Possible cause #1: Components loose where they are fastened to the Back Cover Plate.

- Remedy: Tighten fastening screws.

- Possible cause #2: Connecting Rod is coming in contact with Tower.

|

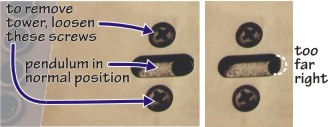

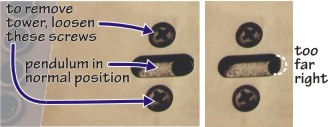

Photo D: Tower and

Photo D: Tower and

Connecting Rod |

If this is indeed the problem, it will be easy to identify even before the unit is removed from the guitar because the B string hole in the String Pulling Pendulum,(visible through the slot in the Back Cover Plate, (see photo E), will be positioned too far back in the slot to allow the insertion of a new B string without moving the Strap Lever. If the Strap Lever has to be pulled in order to insert a new B string, this is a sure sign that the unit was improperly set up and needs to be adjusted. This problem with improper initial set-up is almost always accompanied with a resounding "click" when the StringBender is released and allowed to return to home position. |

- Remedy: Shorten the length of the Connecting Rod by removing the screws that secure the Tower, and rotating the Tower and Connecting Rod as a unit so that the Connecting Rod threads farther into the Clevis.

Photo E: Pendulum, exterior view,

Photo E: Pendulum, exterior view,

correctly adjusted and out of adjustmentOne, or two clockwise turns should do the trick. Re-attach the Tower to the Back Cover Plate and check to make sure the Connecting Rod is not touching the Tower when the StringBender is in the "home" position. The unit should function silently and smoothly now when pressure on the Strap Lever is released and the mechanism returns to its "home" position.

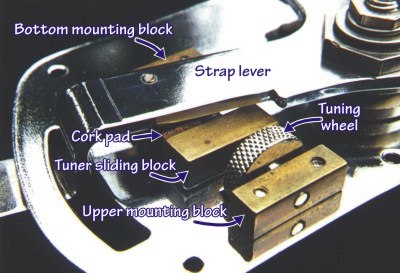

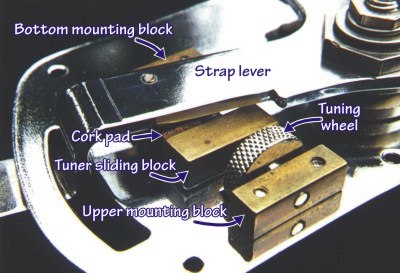

- Possible cause #3: The Cork Pad is missing from the bottom Tuning Mechanism Mounting Block.

Photo F: Tuning mechanism, interior bottom view

Photo F: Tuning mechanism, interior bottom view

- Remedy: Replace Cork Pad.

- Possible cause #4: Strap Lever Stop is loose (see photo F)

- Remedy: Tighten the screw that secures Strap Lever Stop.

- Possible cause #5: Tuning Mechanism is loose.

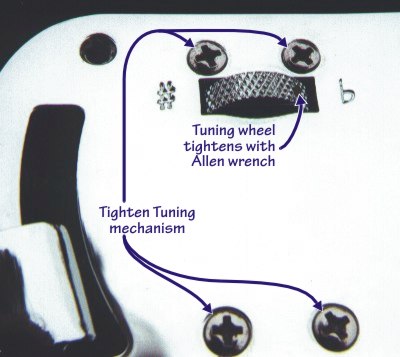

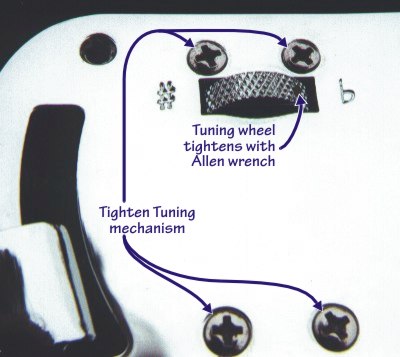

- Remedy: Tighten screws securing Tuning Mechanism (see photo below)

Photo G: Tuning mechanism, exterior view

Photo G: Tuning mechanism, exterior view

Problem C: Clicking sound produced at end of stroke when B-Bender is actuated.

- Possible cause #1: Components loose where they are fastened to the Back Cover Plate.

- Remedy: Tighten fastening screws.

- Possible cause #2: Cork Pad is missing on Tuning Mechanism Sliding Block.

Photo H: Tuning Mechanism, interior top view

Photo H: Tuning Mechanism, interior top view

- Remedy: Replace Cork Pad.

- Possible cause #3: Strap Lever Stop is loose (see photo F)

- Remedy: Tighten the screw that secures Strap Lever Stop.

Possible cause #4: Tuning Mechanism is loose.

- Remedy: Tighten screws securing Tuning Mechanism (see photo G)

Problem D: Loose Tuning Mechanism Sliding Block

- Possible cause: There are rare instances when even though the Tuning Mechanism is securely tightened with its attaching screws, the Sliding Block, (see photo H) has too much clearance between its underside and the Back Cover Plate. If this is the case it will tend to flop around during the function of the StringBender and will produce noise.

- Remedy: Insert a small piece of rubber or cork between one corner of the Sliding Block and the Back Cover Plate.

- Remedy: Another more permanent method is to disassemble the tuning mechanism and carefully sand, mill, or file some material from the bottom of the Mounting Blocks until the excess clearance between the Sliding Block and the Back Cover Plate is eliminated. (Careful though. Don't take too much!)

Problem E: StringBender cannot be tuned.

- Possible cause #1#: Tuner Wheel is loose on its shaft.

- Remedy: Using the proper size Allen hex wrench, tighten the set screw in the Tuner Wheel. (see photo G)

Problem F: The B string returns sharp when StringBender is used.

Possible cause #1: The B string is binding in the B bridge saddle groove.

- Remedy: Lubricate bridge saddle where the B string rides over it. (see photo A)

- Remedy: The bridge saddle may need to be carefully filed and smoothed where the B string contacts it or in rare cases replaced.

Possible cause #2: The B string is binding in the nut.

- Remedy: Re file the B string groove in the nut so that the B string rides freely.

- Remedy: Lubricate nut with graphite or other suitable lubricant. (I like to use oil)

Possible cause #3: Tuning problems can result if any of the Parsons/Green, Fender B Bender components are not working absolutely freely without binding, or if any component mounting screws have become loosened, or if there is possibly some foreign object/objects inside the guitar.

- Remedy: Review above text.

Problem G: Spring sound (boing!) when B-Bender is actuated.

- Possible cause #1: Felt pad missing from inside Return Spring.

(see photo C)

- Remedy: Replace felt pad inside Return Spring

Problem H: StringBender will not return all the way to home position or player finds that the StringBender is being actuated unintentionally.

- Possible cause #1: Not enough Return Spring tension.

- Remedy: Increase Return Spring tension by cutting off a loop/loops from the end of the Return Spring where it attaches to the Return Spring Anchor. (see photo C) Simply cut off one loop at a time and bend down the next loop in line so the Return Spring can again be attached to the Return Spring Anchor. Re-attach the Return Spring, re-install the unit and check the return action. If enough tension is not achieved with one loop removed, than a second, third or more loops may need to be removed until the right "action" is achieved.

If after removing up to six loops from the Return Spring, the tension is still insufficient, a new Return Spring may be necessary. Some of the first guitars fitted with Parsons/Green Fender B Benders were somewhat heavy in weight and were more often troubled with inadequate Return Spring tension.

Some players like more return tension than others. My personal preference is when there is just enough tension for the unit to completely return from any position, (even when the Strap Lever is just slightly pulled up), but no more tension than is necessary. Too much tension will make the Parsons/Green Fender B Bender difficult to use particularly when playing up the neck where there is less leverage available to press down the neck.

Problem I: String Breakage (String breaks 1-1/2" inches from string

ball)

|

- Possible cause #1: The String Pulling Pendulum is manufactured with a "VEE" slot milled into the back side of its top.

- Remedy: This "VEE" is intended to center the B String where it rides over the crown of the Pendulum. Some of the String Pulling Pendulums have the "VEE" slot milled too deep with a sharp edge at its top or point. The 'B' string must make a sharp bend over this edge as it changes its vertical direction from inside the Pendulum and rides over the crown of the Pendulum on its way towards the Bridge Saddle. The original design provided a "VEE" slot that would center the string but would allow it to ride on the rounded top or crown of the Pendulum and not on the edge of the "VEE" slot.

|

Photo V: String rides over VEE

|

The point here is that if the string is riding on the crown of the Pendulum it is unlikely to break. However, if it is riding on the sharp edge of the "VEE" slot it is quite likely to break.

- Remedy: Using a small jewelers file or Dremel, carefully round off the

area at the top or point of the "VEE" slot behind the crown of the String Pulling Pendulum so that the B String has a smooth, rounded crown to ride over rather than a sharp edge.

- Remedy: Shorten the Connecting Rod by threading it farther into the Clevis. (Refer to remedy procedure for Problem B, Cause number two). When the Connecting Rod is shortened by threading it farther into the Clevis, the position of the String Pulling Pendulum is changed, rocking it back slightly. This will cause the string to ride more as it should, over the rounded crown or top of the Pendulum rather than over the sharp edge of the "VEE" slot.

- Remedy: By inserting 3/16 inch (inner diameter) spacer washers between the base of the Tower and the Back Plate, the String Pulling Pendulum and Tower can be made to protrude a little higher through the Ferrule Ring on the face of the guitar body thus causing the B String to ride more on the rounded crown of the Pendulum and not on the sharp edge of the "VEE" slot.

Where the Fender B Bender is installed in guitar bodies that are thicker than a standard Telecaster body, this should be done during the installation.

If after reading the above text and using the procedures suggested the technician is still unable to discover the cause of a problem or manifest the cure, feel free to contact me via email

or call me at the StringBender Custom Shop: (707) 964-8146.

Happy StringBending!

|

|